During product matching, R&D application and actual developing, Sino project department will make foreseen inspection and check on the product, including developing rapid prototyping sample, improving matching, and matching mould, etc..  So as to avoid mistakes, and achieve higher grade matching standard more precisely.

So as to avoid mistakes, and achieve higher grade matching standard more precisely.

Make analog testing before model, and by using professional MOLDFLOW software, analyze injection process, gate assignment, temperature control, cooling time,etc., improve mould design, and settle design blind.

QC department will inspect product and submit mould inspection report 24 hours after mould testing. It will make full range inspection and analysis on product size, appearance, injection process and physical performance. For different product, we have different inspection standard and inspection tool. In lab, we make different testing for product bearing pressure, impulse loading, tensile strength, impact resistance, and so on. QC department submits detailed opinions on improving rejected product. We has abundant experience, and applys to mould production, so as to offer perfect solution for more customers. Along with the continuous improvement of equipment, our product inspection has become more professional. The company plans to buy more measuring equipment in 2010, and provide better inspection service.

Select high quality spare parts and imported mould material, make inspection on material, and make sure the quality. Control the processing, size, and quality.

After finish the mould tooling, make inspection on core and cavity.

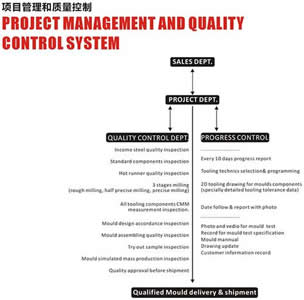

Production control:

Processing Technic Department:

Technicians of processing technic department should audit modeling before mould production and make arrangements for mould tooling. It can ensure the mould being delivered successfully within shortest and rational delivery time. Also, it can avoid long production cycle and material waste problems that are caused by improper processing.

Proceeding Department:

Staffs in proceeding department keep tracing the mould processing every day, collect schedule of each mould’s tooling steps by photos, and provide processing report for sales department. On the meantime, they coordinate with project director to monitor production processing and equipment modulation, and coordinate with each department to arrange mould machining. They handle the tooling delaying problems positively, and ensure the production department retrieves the time in the next step.

Order management

Project manager-sales people-quality and production form (catalogue pages)

Order flowsheet: